Sodium Bentonite, also known as sodium clay, is a type of aluminum silicate clay that contains a high amount of sodium within its crystal structure. A defining feature of this type of bentonite is its exceptional swelling capacity and ability to absorb large volumes of water. This characteristic makes sodium bentonite an ideal material for use as a sealant, adhesive, and a barrier against water and chemical infiltration in various industries.

Due to its unique properties, sodium bentonite has gained significant importance in numerous industrial and agricultural processes. Furthermore, its ease of use and cost-effectiveness are additional factors contributing to its widespread popularity.

Production of Sodium Bentonite

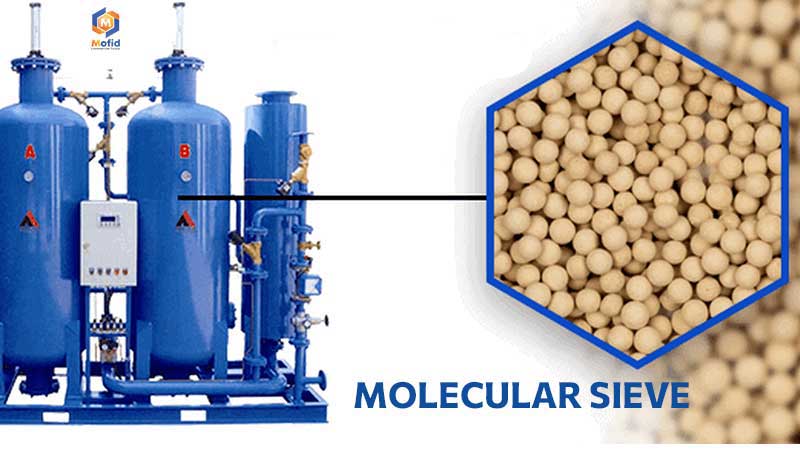

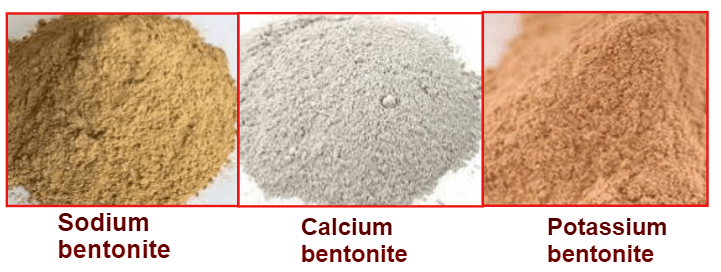

Sodium bentonite is mined from various deposits worldwide and is often found alongside other types, such as calcium and potassium bentonite. The extraction process involves separating mineral layers and refining them to achieve a high-purity final product.

In cases where natural sodium bentonite does not meet market demand, calcium bentonite can be converted into synthetic sodium bentonite by treating it with substances like caustic soda. This process enables producers to meet the needs of different industries efficiently.

Applications of Sodium Bentonite

Sodium bentonite’s affordability and versatile properties make it indispensable across multiple industries. Its ability to absorb up to 15 times its dry weight in water, combined with adhesive and high impermeability characteristics, positions it as a crucial material in various fields:

1. Agricultural Applications

- Soil Moisture Retention: Ideal for arid and low-rainfall regions, sodium bentonite helps retain soil moisture, promoting better plant growth.

- Soil pH Control: Regulates soil acidity in saline and low-yield lands.

- Preventing Mold in Stored Products: Absorbs excess moisture in silos and storage facilities, preventing spoilage.

- Sulfur Fertilizer Production: Used in combination with sulfur to produce fertilizers that enhance agricultural productivity.

2. Livestock and Poultry Feed Applications

- Detoxification of Digestive Systems: Reduces the impact of toxins and improves feed quality for livestock.

- Pellet Formation: Enhances the strength and durability of animal feed pellets.

- Moisture Absorption in Bedding: Prevents harmful fungal growth and improves the health of livestock and poultry environments.

3. Drilling Industry Applications

- Oil and Gas Well Drilling: Due to its gel-like properties, sodium bentonite is used to prevent water intrusion and stabilize well walls during drilling operations.

- Earthing Wells: Reduces soil resistivity and protects electrodes in electrical grounding systems.

4. Foundry Applications

- Mold Strength Enhancement: Combined with sand to create durable molds for metal casting.

- High Thermal Resistance: Retains its properties at high temperatures, making it suitable for casting molten metals.

5. Construction Industry Applications

- Sealing and Insulation: Prevents moisture penetration in building structures.

- Wall Support in Excavation: Creates hydrostatic pressure to prevent wall collapses during digging.

- Compatibility with Cement: Works well during concrete curing processes, ensuring structural integrity.

Benefits of Sodium Bentonite in Various Industries

Sodium bentonite stands out for its multifunctional properties, such as exceptional water absorption, chemical resistance, and versatility. Its cost-effectiveness and adaptability make it a valuable resource in agriculture, construction, drilling, and other industries, ensuring efficiency and improved outcomes in applications where it is employed.

Additional Benefits of Sodium Bentonite

- Water Conservation in Agriculture: Due to its high water absorption and retention capacity, sodium bentonite plays a significant role in reducing water usage in agricultural applications.

- Self-Healing Capability: In drilling wells and channels, sodium bentonite expands upon absorbing water, effectively filling cracks and gaps.

- High Resistance to Moisture Penetration: This property makes sodium bentonite an excellent sealing material for insulation purposes in the construction, oil, and gas industries.

Differences Between Sodium Bentonite and Calcium Bentonite

The swelling capacity of sodium bentonite is significantly higher than that of calcium bentonite. Sodium bentonite can absorb several times its dry weight in water, making it ideal for applications requiring effective sealing and insulation. In contrast, calcium bentonite has a lower swelling capacity, limiting its use in scenarios that demand high absorbency.

When it comes to water retention, sodium bentonite outperforms calcium bentonite by retaining water more effectively. This makes it particularly suitable for agricultural purposes where water conservation is essential. On the other hand, calcium bentonite, with its moderate water retention capabilities, is more commonly utilized in products like cat litter and cosmetics.

Another key difference lies in their cation exchange capacity (CEC). Sodium bentonite has a higher CEC, which enhances its efficiency in soil improvement and detoxification applications. Conversely, calcium bentonite’s lower CEC reduces its effectiveness in these areas.

In terms of practical applications, sodium bentonite is widely used for drilling muds, liners, and industrial sealing due to its superior swelling and sealing properties. Meanwhile, calcium bentonite is favored for health and beauty products, animal feed, and non-swelling applications, making it versatile in its own right.

Sodium and calcium bentonite differ in terms of structure and applications. Sodium bentonite has a higher water absorption and swelling capacity, giving it a broader range of uses. On the other hand, calcium bentonite is primarily utilized for ion and toxin absorption, making it more suitable for purification and cleaning industries.

Price of Sodium Bentonite

The price of sodium bentonite depends on factors such as mineral grade, water absorption capacity, and the required mesh size. Additionally, extraction, processing, and transportation costs influence the final price. For up-to-date pricing information, you can contact the sales department at Mofid Company.

Purchasing Sodium Bentonite